ME360 ASSIGNMENT 2 - SKATEBOARD

Design Goals:

To model a skateboard that can hold a skater of 180 lbs, with a shoe size of up to US 12, with maximum vertical displacement no more than 0.375", and a safety factor of 3. This should be done using SolidWorks and FEA.

Constraints:

- Skateboard must hold 180 lbf

- Accommodate skaters up to shoe size US 12.

- No more than 0.375"of vertical displacement.

- One pin joint, one roller joint

- Factor of Safety: 3

Relevant Information:

The most relevant information to this project is a lot of coursework from ME306, ME305, and ME358, all of which discuss material properties like Elastic Moduli and Poisson’s Ratios in different applications. These material properties drive decisions in material choice – the skateboard should be rigid enough to not permanently deform to typical stresses of riding but should be elastic enough to endure long term cyclic stresses. The skateboard should also be cost effective and lightweight enough to be able to ride it comfortably.

Design Approach:

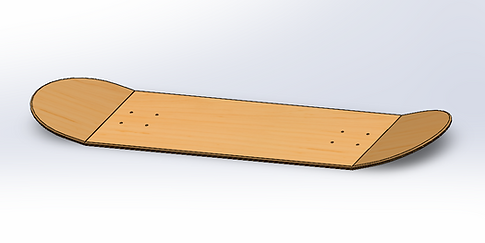

The first design aspect to look into would be the geometry. This design is heavily inspired by traditional skateboards meant for tricks, as opposed to cruisers or longboards which are more meant for riding. Skateboards for tricks have a traditional / conventional sizing chart, so for a rider of about size US 12 feet, they would be looking towards a board that is between 8” and 8.5” wide. Primitive Skate provides a convenient template for skateboards of various sizes, so for a skateboard with a width of 8.1”, the respective length would typically be 31.75”. These templates also provided rough outlines for where the trucks would be on the board, giving a rough margin for where the pin and roller supports should be underneath the board. The typical thickness of a skateboard is 0.5”. The sketched skateboard was also filleted with a radius of 0.2” to make it look and act more like a skateboard.

.jpg)

With the general shape of the deck done, the next step would be determining where the supports would be in relation to the deck. With some quick research, the typical height of medium sized trucks is about 50mm (~2in) from the bottom of the deck to the axel holding the wheels, and typical medium sized wheels are about 52mm-56mm (~2in) in diameter. The distance from the bottom of the deck to the ground should be approximately 3”. The width of the pseudo-trucks and wheels was found with some more research on how far apart the mounting holes on the trucks are, about 2”.

As per the problem statement, the front support should be a fixed pin joint, and the back support should be a roller. These aspects can be assigned during the FEA phase. An important consideration is that these tests assume the geometry of a skateboard is a solid piece of shaped material, but realistically a skateboard is about 7-8 ply, and molded to a special contour – not simply a flat board with raised edges as modeled. The rectangular truck-wheel assembly is strictly for simulation purposes.

Material Selection:

The analysis of this model was relatively straightforward. Once the material list was assembled, all that was left was to set up a test scenario and apply each material to the test to find the vertical displacement of the skateboard.

The supports to mimic a truck-wheel assembly were assigned with the front as a pin support, and the back as a roller support (as stated in the problem).

Next was applying the force to the system: 180lbf with a factory of safety of 3 becomes 540lbf. To ensure the worst-case scenario, the 540lb force was loaded with the width of about a size US 12 foot (4.25"), on the weakest part of the board, the center of the two supports.

Given the metrics above, the most outstanding contender is Sweet Birch, because it has the highest Young’s Modulus, lowest weight density, lowest cost, and smallest amount of vertical displacement (driven by Young’s Modulus).

Finite Element Analysis (FEA):

Considerations for material selection of a skateboard are elasticity, weight density, and material cost. The most common type of material for a skateboard is maple, so by this merit, it automatically entered the race for material selection. According to the “Wood Handbook” by Green, Winandy, and Kretchmann, the highest Young’s Modulus value for maple was 12,600 MPa for Sugar Maple. The largest value ingeneral, given on this list was Sweet Birch with a Young’s Modulus of 15,000 MPa, and next, Shagbark Hickory with a Young’s Modulus of 14,900 MPa.

Cost metrics were established by calculating cost per cubic inch of each material with estimates from "bellforestproducts.com". These metrics omit the cost of actually manufacturing the skateboard, but because they are all held to the same standard and they are all wood it should be a negligible issue.

Shown in purple is the 540lb force over the 4.25" in the center of the board; a US 12 size foot would hang over the board, which is why the force meets the edges of the board.

Shown in green are the pin and roller supports. The pin support on the left restricts X,Y, and Z movement, and roller support on the right restricts movement in the X and Y planes.

Above is the FEA for Sugar Maple. The maximum vertical displacement is 2.011mm or 0.0791in.

Above is the FEA for Shagbark Hickory. The maximum vertical displacement is 1.701mm or 0.0669in.

Above is the FEA for Sweet Birch. The maximum vertical displacement is 1.689mm or 0.0684in.

Optimization:

The easiest way to optimize for weight with FEA is to reiterate the thickness of the deck until it meets the maximum displacement of 0.375".

Instead of 0.5" thickness, the chosen thickness became 0.25", resulting in a maximum displacement of 11.73mm or 0.461in. This exceeds the maximum displacement. This result can be reiterated to get the maximum displacement even closer to 0.375". The next test showed 0.28" thickness resulting in a maximum displacement of 8.469mm or 0.333in. This result can be taken even further for maximum optimization, but this result is plenty.

Conclusion:

The final iteration of this design is made of Birch. With a length of 31.75", width of 8.1". Below is a drawing with more detail on the placement of the truck mounting holes. The main difference between this design and the preliminary version is the thickness of the board from 0.5" to 0.28". The mass of the final design is 1.59 lbm.

Considerations for the future are that tests could be run with a more realistic truck-wheel assembly. As stated before, this design also omits the fact that skateboards are usually built with 7-8 ply wood. These test cases assume it is a single, solid material. Also, this skateboard model omits special contours that add strength, mitigating fracture points like corners. Generally though, this model is a relatively stable estimate of the tests at hand, and a more realistic testing environment would likely improve results rather than deteriorate them.